In 1927, Woodruff’s Ice Cream reported a volume of business so great that they couldn’t meet the demand for their ice cream. That year they exceeded their expectations by retailing 20,000 gallons of ice cream. To accommodate their increasing business, the ice cream plant was moved to a new location on North Main Street. The location was known as the McClaskey Building which previously housed Gallatin Motor Company when it operated as a Ford car dealership.

Woodruff Ice Cream operated as one of Gallatin’s only manufacturing plants for nearly 50 years. John Woodruff opened for business working at the rear of the Woodruff building for a number of years. His wife, Ivo, assisted as eventually did their son, Frank. Declining health contributed to John’s decision to close

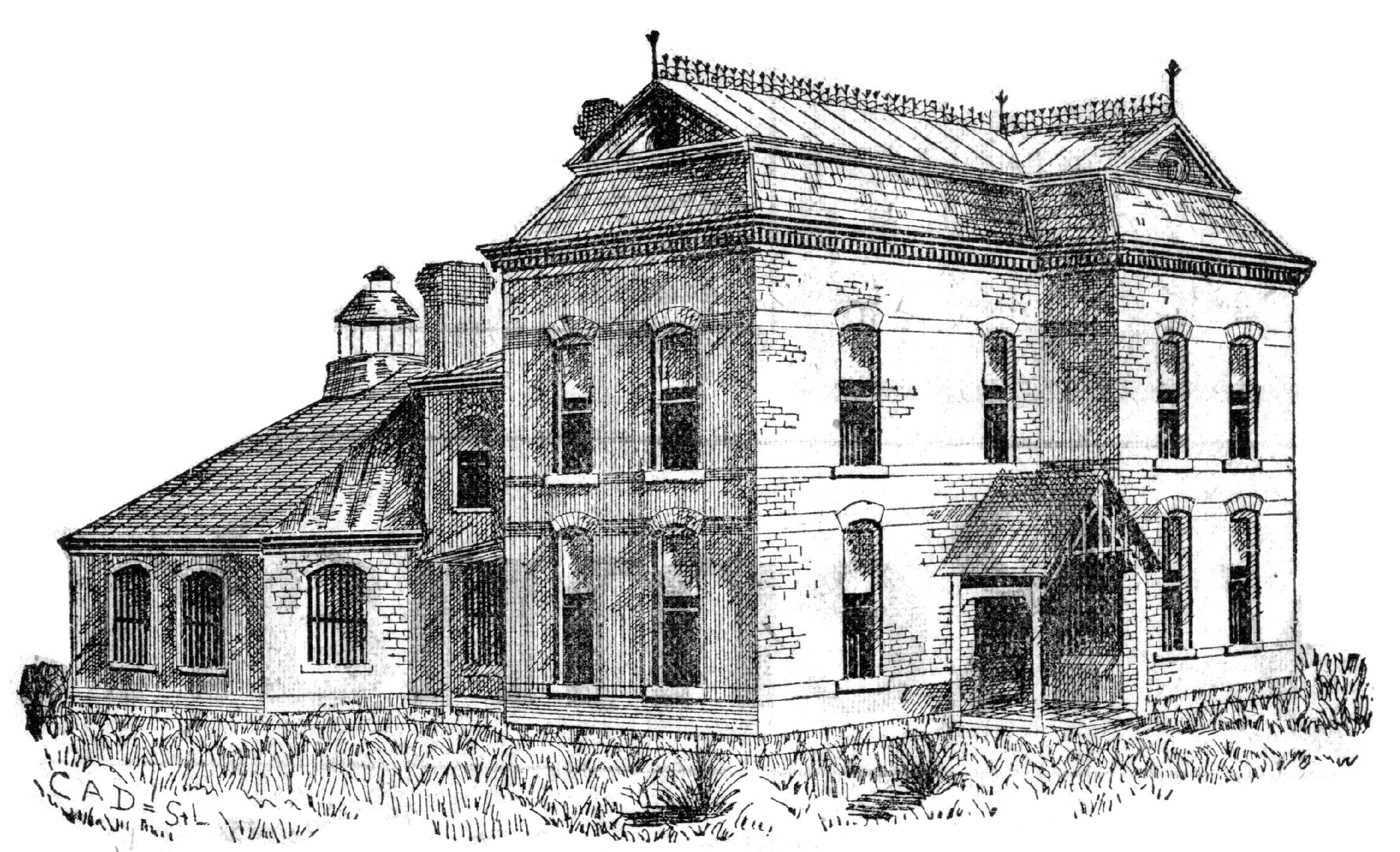

This bus and feed barn was built by J.W. McClaskey at 211 North Main Street in Gallatin, MO. The building later housed a car dealership when an elevator was installed to make use of the second floor for vehicles. Later still the building housed Woodruff Ice Cream. (photo date unknown)

Small rooms ran down both sides of the former garage about half the length of the building. Some were used for company offices. The remainder were used for living quarters. The machinery was located at the back of the building.

On May 3, 1928, the Gallatin North Missourian quoted Mr. Woodruff as saying, “We started out with four walls and now have a place that is the last word of factories of this kind.”

The first “freeze” in the new location was approximately 600 gallons of ice cream. One of the main features of the plant was the storage or refrigerator room which had a capacity for holding several thousand gallons of ice cream. They expected to make 500 or 600 gallons of ice cream per day during the rush part of the season and had the potential to make 800 gallons a day.

During the peak season the company would employ five or six men.

The business was among the first ice cream manufacturers to package in “sealright” round pint and quart containers. A mix was made six days a week and each was frozen the next day. Ice cream was made into retail size containers, five gallon cans used for cone dipping, and ice cream bars.

To make bars, trays were filled and sticks inserted through a rack. The next day, the bars were cut, chocolate coated, individually sacked, and packed a dozen to a bag.

The business closed in 1975.

To my knowledge, that’s not a “commemorative coin”, it’s a token to take a ride from the train station to the Woodruff Hotel.

Makes sense. I appreciate the comment, David. It’s a challenge trying to get all the details straight. Thanks!

This is not me complaining. Just sharing.

Appreciate all you have done and continue to do Darryl.

Those tokens were first made of aluminum, and later of plastic, the ones I’ve seen in green or red. I don’t know if different materials or colors had different purposes.

Better information is exactly what I want. I am embedding your information into the image so that regardless of its future use, we do not lose the identification and details associated with the image. Hopefully, over time, we’ll acquire lots of accurate, correct information for most of the images throughout this website. Thanks, David. We want your input!

(FYI… the token is now relocated on the Woodruff Hotel webpage with corrected info)